A heat exchanger is a device that transfers part of the heat of a hot fluid to a cold fluid, also known as a heat exchanger. Heat exchangers play an important role in chemical, petroleum, power, food and many other industrial productions. In chemical production, heat exchangers can be used as heaters, coolers, condensers, evaporators and reboilers, etc., and are widely used. . Due to the wide application of heat exchangers and many application places, the heat exchangers on the market already have various functions to meet different processes, but because of the variety of types of heat exchangers, many friends are dazzled and do not know how to choose. So heat exchanger exporter Sanqian will share it with you in this article.

There are many types of heat exchangers, but the principles are almost the same. The equipment that can realize the heat transfer process is called heat exchange equipment. The heat will be transferred to another fluid through the fluid. The higher the heat transfer efficiency, the more heat transfer. a lot of. Let's not talk nonsense, let's get to the point, what are the types of heat exchangers?

Shell and tube heat exchanger

The process of the shell and tube heat exchanger type is as follows: tube side: the fluid goes inside the tube, shell side: the fluid goes outside the tube. The fluid in the tube flows from one end of the heat exchange tube to the other end in one pass; in the U-shaped tube heat exchanger, the fluid in the tube flows from one end of the heat exchange tube through the U-shaped curved section to the other end, forming two passes.

Heat exchanger exporter Sanqian introduces the common types of shell and tube heat exchangers as follows:

1. Fixed tube sheet heat exchanger

2. Floating head heat exchanger

3. U-tube heat exchanger

4. Stuffing Box Heat Exchanger

Plate heat exchanger

1. Spiral plate heat exchanger

The structure of the spiral plate heat exchanger is made by two parallel steel plates on a rolling bed. It has a pair of cylinders with spiral channels, plus a top cover and inlet and outlet pipes.

2. Plate Heat Exchanger

It is made of thin metal plates, and the plates in the frame are assembled on the bracket. The edges of the adjacent plates are pressed with gaskets, and there are round holes at the four corners to form channels.

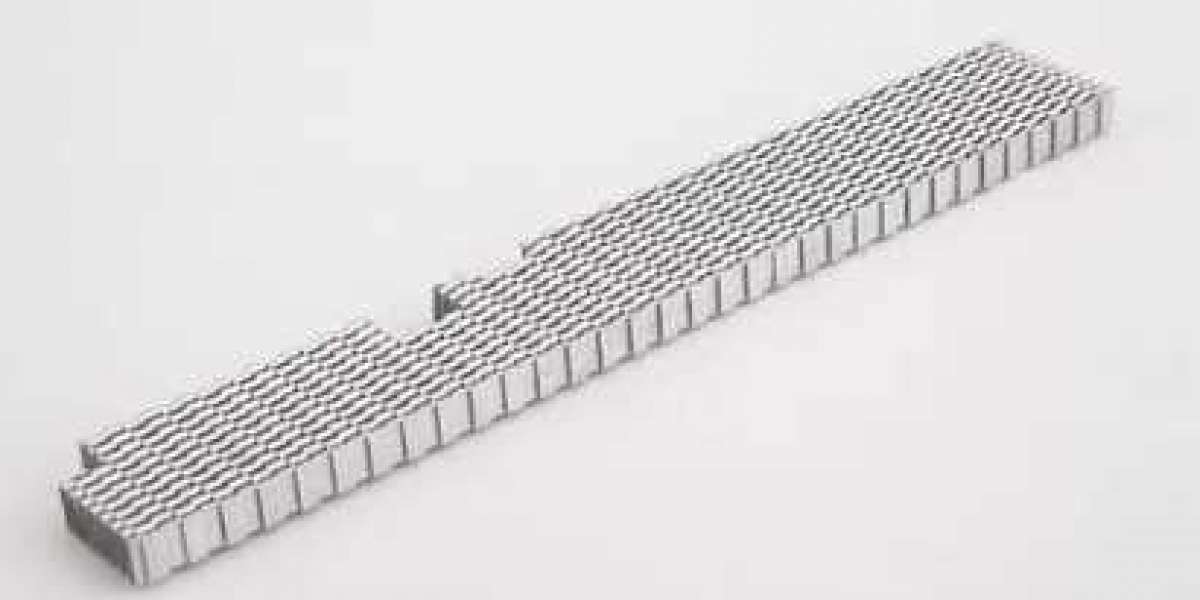

3. Plate-fin heat exchanger

The plate-fin heat exchanger is composed of baffles, seals, fins, baffles, and guide fins, and between the baffles, the guide fins, seals, and fins are combined to form a channel.

Casing heat exchanger

The casing heat exchanger is also a type of tube heat exchanger, mainly because different standard pipes are connected into concentric pipes, the outside becomes the shell side, and the inside of the pipe is the tube side, and the two media will be in the tube side and the shell side. Internal reverse flow to achieve the effect of heat exchange.

The above is the common classification and introduction of various heat exchanger types shared by heat exchanger exporter Sanqian with you. I believe that everyone will understand after reading this article. If you want to know more, please contact us.